How to Embed LED Lights in Concrete?

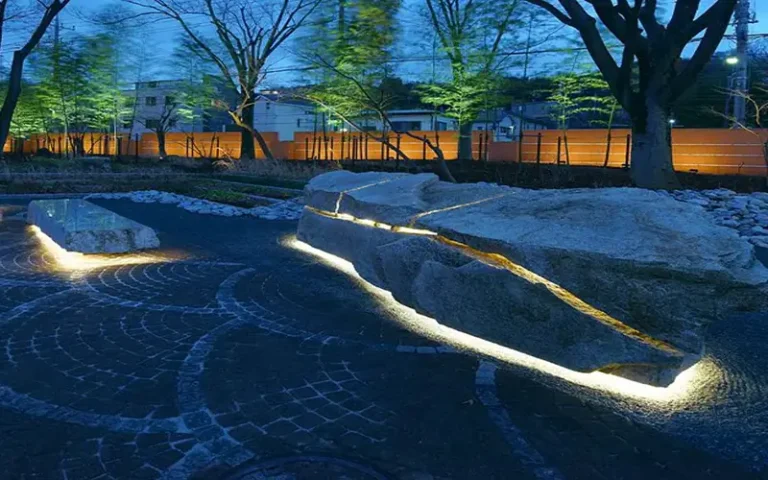

Many people choose to embed LED lights in concrete to add a touch of modern beauty and functionality to a cold and ordinary space. For example, to illuminate outdoor driveways, patios, and indoor floors, embedding LED lights in concrete is a durable and beautiful solution.

This article will introduce in detail whether LED lights can be embedded in concrete and how to install LED lights in concrete.

Which Concrete Can Be Used to Install LED Light?

Before considering installing LED lights in concrete, we need to understand concrete in general. And not all types of concrete are suitable for installing LED light.

The choice of concrete is critical to ensure the durability, strength, and optimal performance of embedded LEDs. For most engineering applications, standard Portland cement concrete is suitable due to its sturdiness and versatility.

What are the Different Concretes to Choose From?

High-performance concrete: It has excellent durability and resistance to environmental stresses, making it ideal for outdoor installations where LED lights may be exposed to the elements.

Fiber-reinforced concrete: Fiber-reinforced concrete is suitable for areas that are subject to heavy loads or frequent traffic. It can provide additional strength and reduce the risk of cracking.

Decorative concrete: For aesthetic purposes, you can choose a decorative concrete mix that contains colored aggregates or embossed patterns to enhance the visual appeal of the LED lighting installation.

Does Embedding LED Lights in Concrete Dissipate Heat?

When embedding LED lights in concrete, we consider heat dissipation one of the main considerations. While LEDs are more efficient than traditional light sources, they still generate some heat. So proper heat management is essential to maintain the life and performance of the lights.

Can concrete dissipate heat?

Concrete itself can act as a heat sink, which can help dissipate the heat generated by the LED.

- Thermal conductivity: Concrete has moderate thermal conductivity, although it is not as effective as metal. However, it absorbs and dissipates heat to a certain extent.

- Thermally conductive materials: Using thermally conductive adhesives or encapsulants can enhance heat transfer from the LED to the concrete.

- Airflow and ventilation: Ensuring adequate airflow around the embedded LED can enhance heat dissipation. This may involve designing the installation with ventilation channels or using heat sinks.

- Heat sinks: Incorporating heat sinks inside the LED profile can improve thermal management. These components help dissipate heat from the LED and disperse it into the surrounding concrete.

How to Embed LED Lights in Concrete?

If you want to embed LED lights into concrete, you can refer to the step-by-step guide below

Planning and designing:

Determine the location and design of the LED installation. Consider the spacing, pattern, power supply installation location, and overall look you want to achieve.

Prepare the concrete form:

Set up the concrete form according to your design specifications. Make sure the form is firm and level.

Create channels or grooves in the form where the LED lights will be placed. These channels will accommodate the LED light strips or fixtures.

Mount the LEDs:

Place the LED light strips or fixtures in the prepared channels. Make sure they are firmly positioned and aligned according to your design. If you are installing outdoors, be sure to choose a waterproof fixture.

Pour the concrete:

Carefully pour the concrete into the form, covering the LEDs and wires. Use a trowel or spatula to smooth the surface and remove air bubbles. Allow the concrete to cure for the specified curing time. Protect the area from disturbance during the curing process.

Test the work:

Once the concrete has fully cured, inspect the LED light to ensure it is working properly. Take a closer look to see if any additional finishes or sealants need to be applied to enhance durability and aesthetics.

Summary

Embedding LED lights into concrete is a lighting solution that enhances the functionality and beauty of a space. By understanding concrete types, heat dissipation, and the correct installation process, you can achieve a durable and visually stunning LED lighting setup. We are an LED strip lights manufacturer, pls contact us if you any interested.

FAQs

Waterproof and durable LED light, such as IP67 or IP68-rated LED light strips or fixtures, are suitable for embedding in concrete. This is because these types of LEDs are designed to withstand moisture and harsh conditions.

Use adhesive or clamps to secure the LED lights in the channels or grooves in advance. Before pouring the concrete, ensure that the wires are also secured and properly aligned to prevent movement.

Answer: Concrete can act as a heat sink. The best way to dissipate heat is to add a heat sink inside the LED housing or use thermally conductive materials to enhance heat dissipation. Ensuring adequate ventilation around the installation also helps.

The concrete should be thick enough to completely cover the LED lights and provide adequate structural support. Typically, a thickness of 3 to 4 inches is sufficient, but it also depends on the specific situation.